PACKAGING

Explorations in the creation and application of natural materials.

DESIGN FOR BEHAVIOR

GONE: Intuitive Sustainability

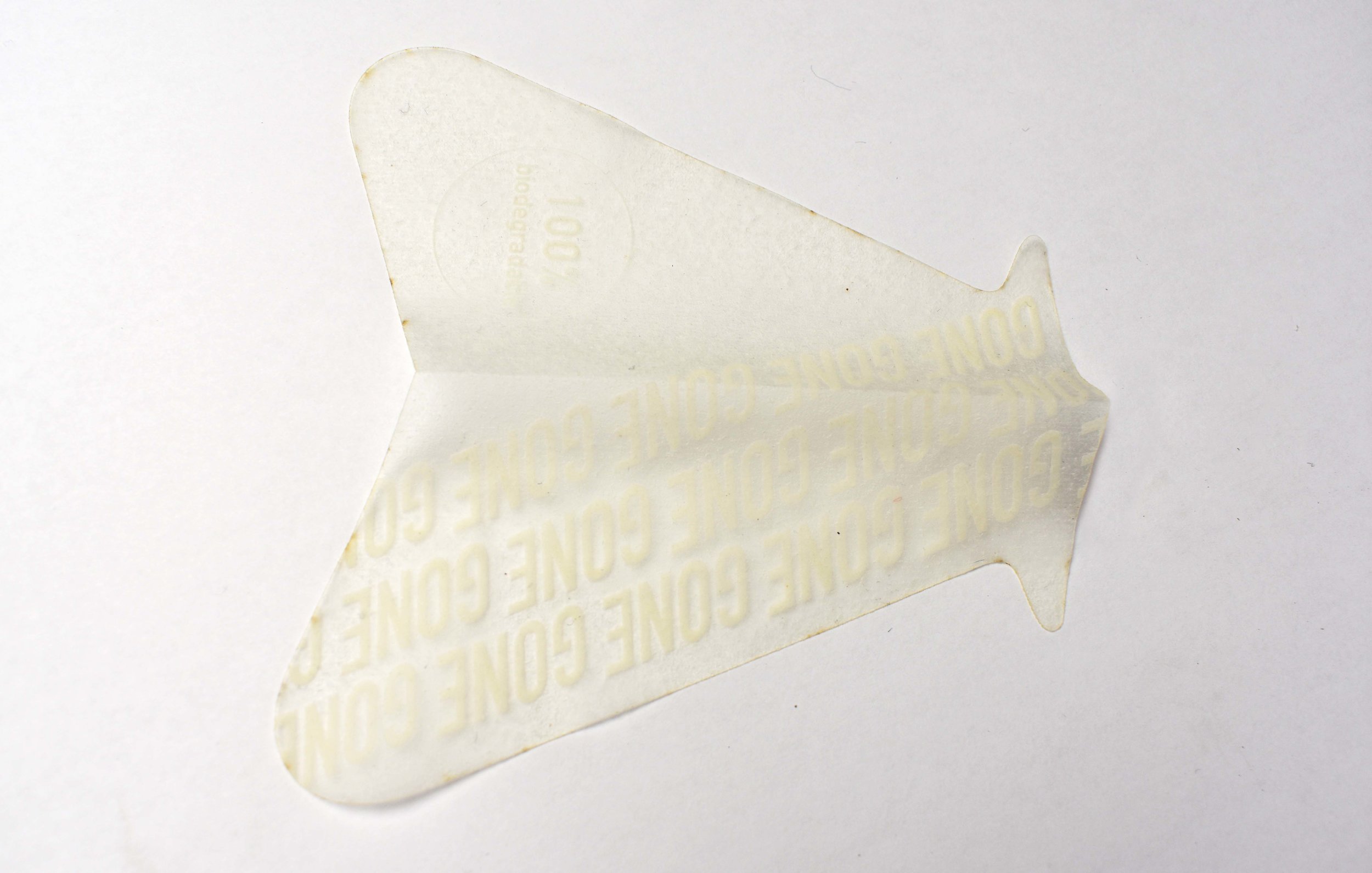

This packaging concept uses naturally-derived, quickly-degrading bioplastic to lessen the environmental impact of single-use packaging. Using simple grocery store ingredients, a unique bioplastic film was developed and crafted to form the container for an energy gel: a nutritional supplement often used during endurance sports like running or cycling. Existing energy gels are made from a plastic-coated foil which is neither recyclable nor compostable - and because these are often consumed in the middle of a workout or a race, athletes must choose either to carry the used, sticky package for the remainder of their workout, or to drop it on the ground and create litter. Unfortunately, between habit and accident, gel packets are left behind very often. Because of the prevalence of this kind of litter in athletic events, a cleanup crew is typically required to sweep the course for trash left behind by participants.

“Gone” aims to minimize a gel’s environmental footprint at every stage of its life cycle, from beginning to end. Its simple material makeup means that it can be thrown on the side of the road where rainfall and local critters will break it down in a matter of days. It ultimately provides an opportunity for the user to choose sustainability and convenience at the same time.

Patented. US D885,198 S

Modeled by Danielle Morsehead, Team Twenty20.

DESIGN FOR MANUFACTURING

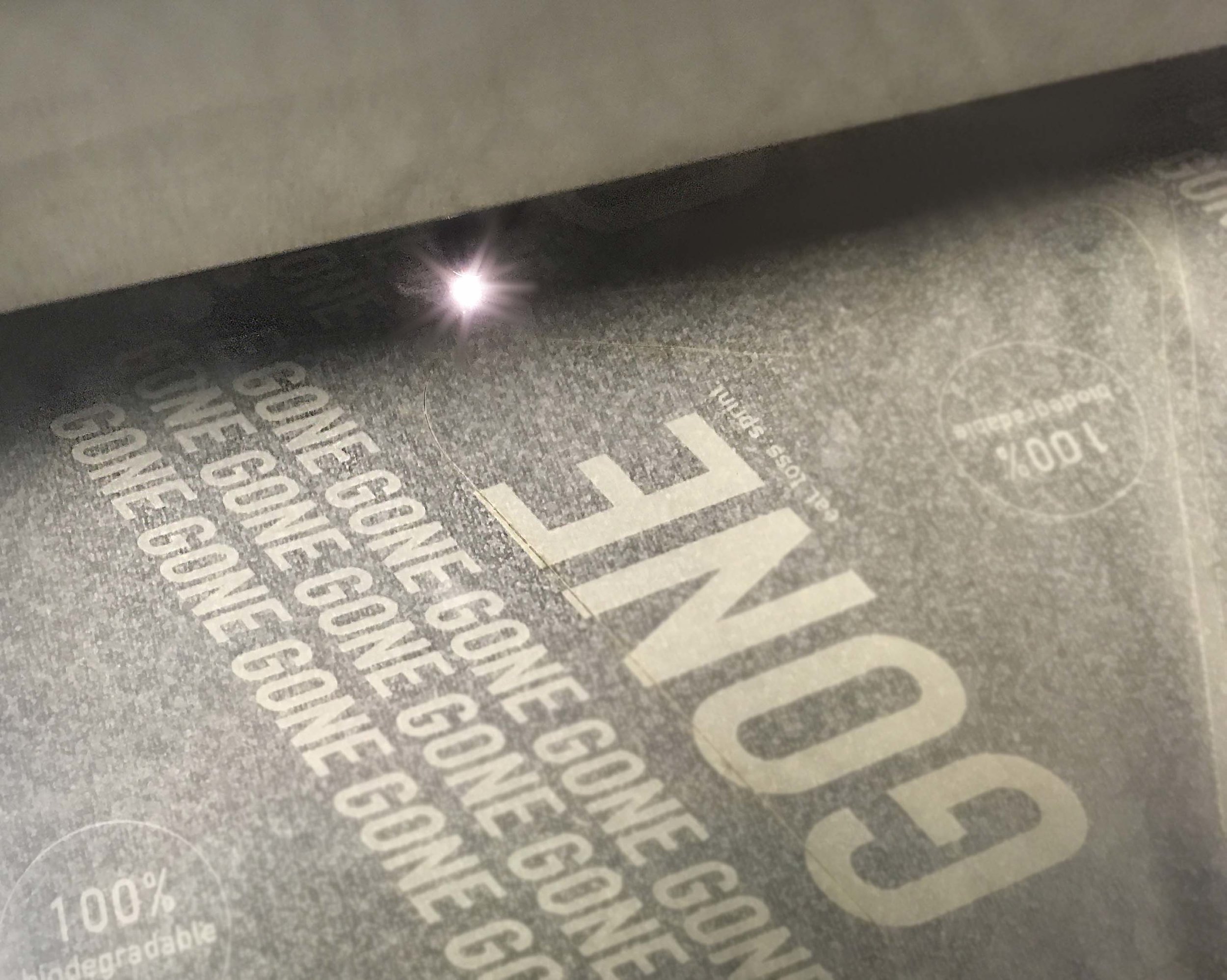

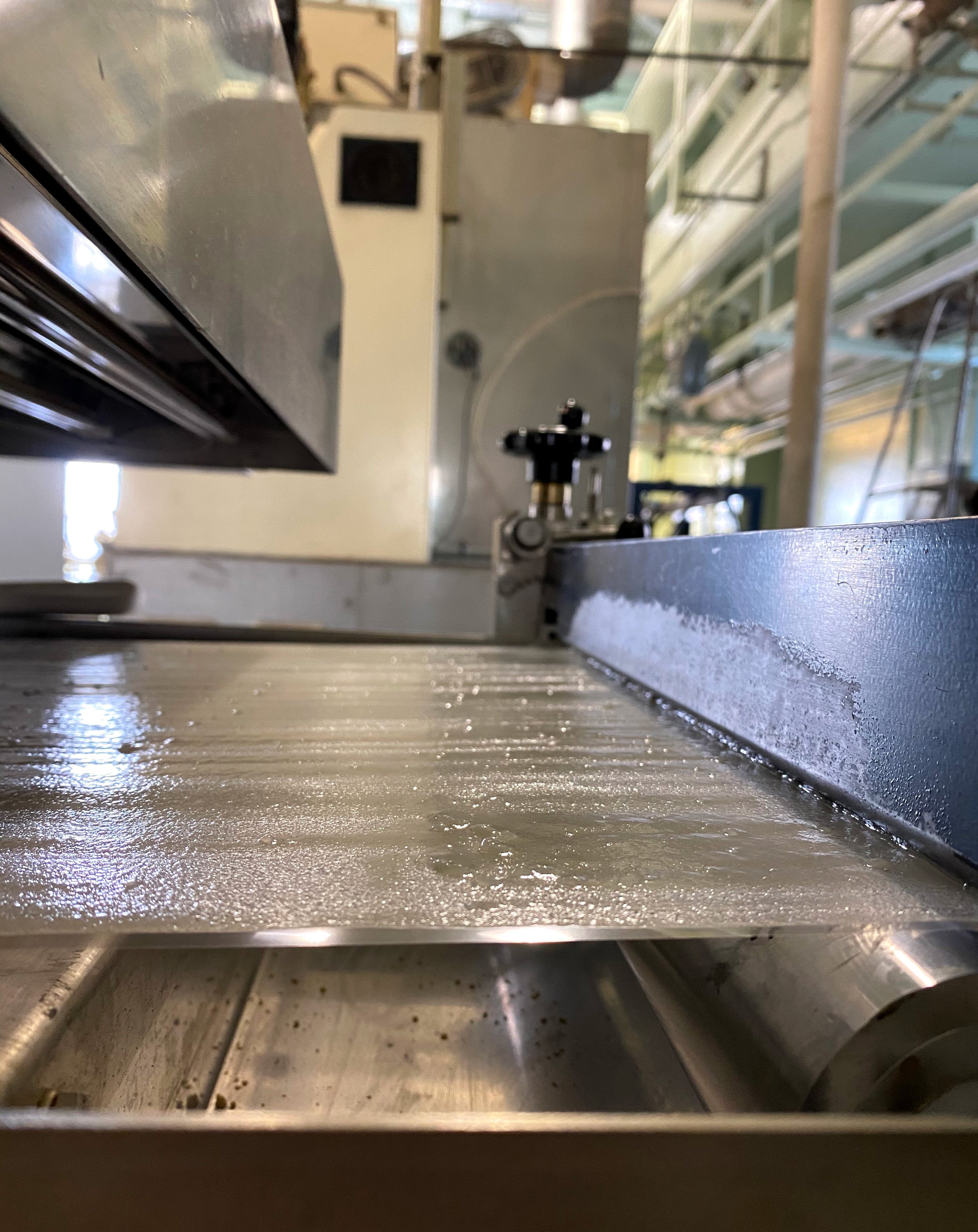

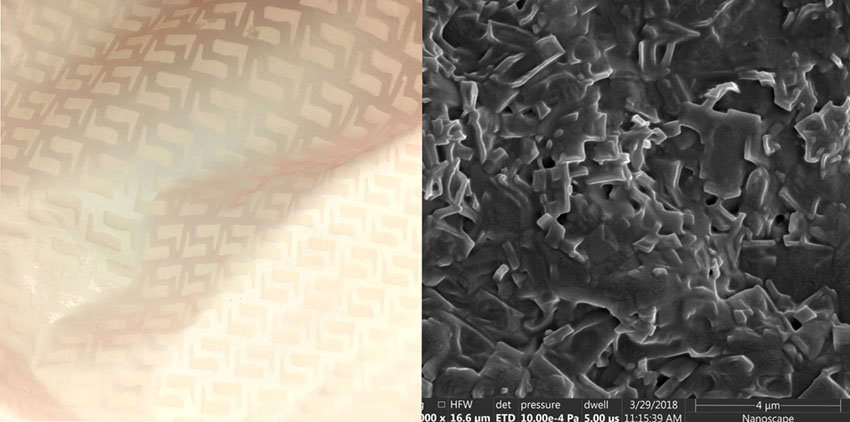

User testing revealed a major barrier: the uneven, organic texture of the home-made bioplastic material felt gross when compared to modern plastic films. Experimenting with different manufacturing and processing methods, I looked for ways to give this purely organic material the same artificial, manufactured aesthetic that’s familiar to the typical consumer. While the initial experiments appeared rough around the edges, they began to look more precise with better tools. Laser-cutting allowed a way to make irregular sheets of material appear consistent. I later began exploring how to produce consistent sheets of material at an industrial scale, using extrusion tools at the USDA research center in Berkeley, CA.

The amount of energy and engineering complexity required to make a new material is a major challenge to their development on a larger scale. Bioplastic and petroleum-based plastics are not one-for-one; the new material has unique properties and necessitates new manufacturing methods which are energy- and capital-intensive to implement.

MATERIAL DEVELOPMENT

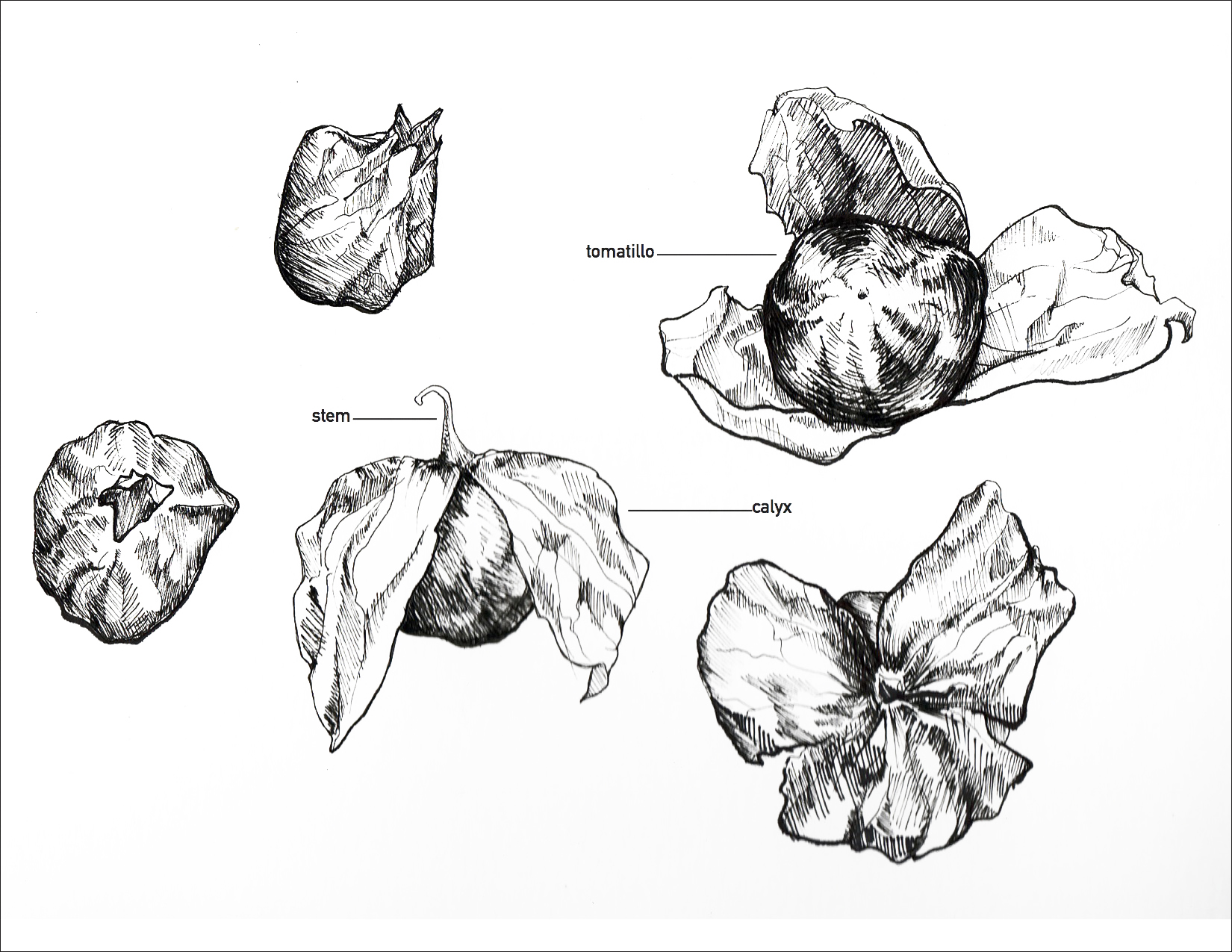

This exploration of material possibilities began as response to the widespread use of non-renewable material resources for ephemeral products (i.e. plastic bags and cups). Driven by the cradle-to-cradle principle, I evaluated every product as a complex series of inputs and outputs that interact directly with the surrounding ecosystem. I also looked to “packaging” that can be found in nature for inspiration. Tomatillos and ground cherries, for example, are protected by a papery outer layer called a "calyx" (from the Ancient Greek word κάλυξ (kálux) meaning "husk”), and these fruits can be found in the grocery store with their natural packaging intact because it ensures preservation without artificial packaging.

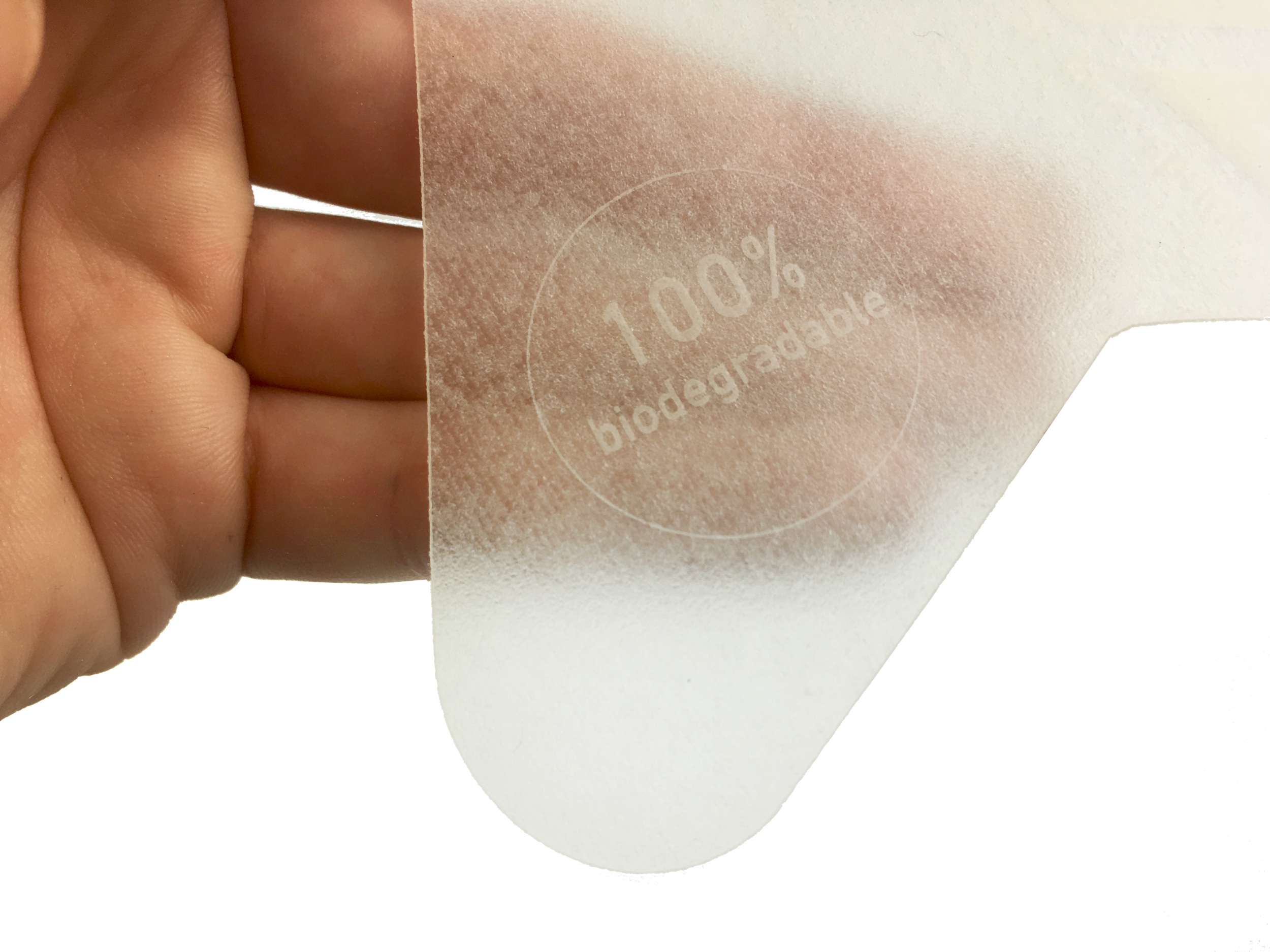

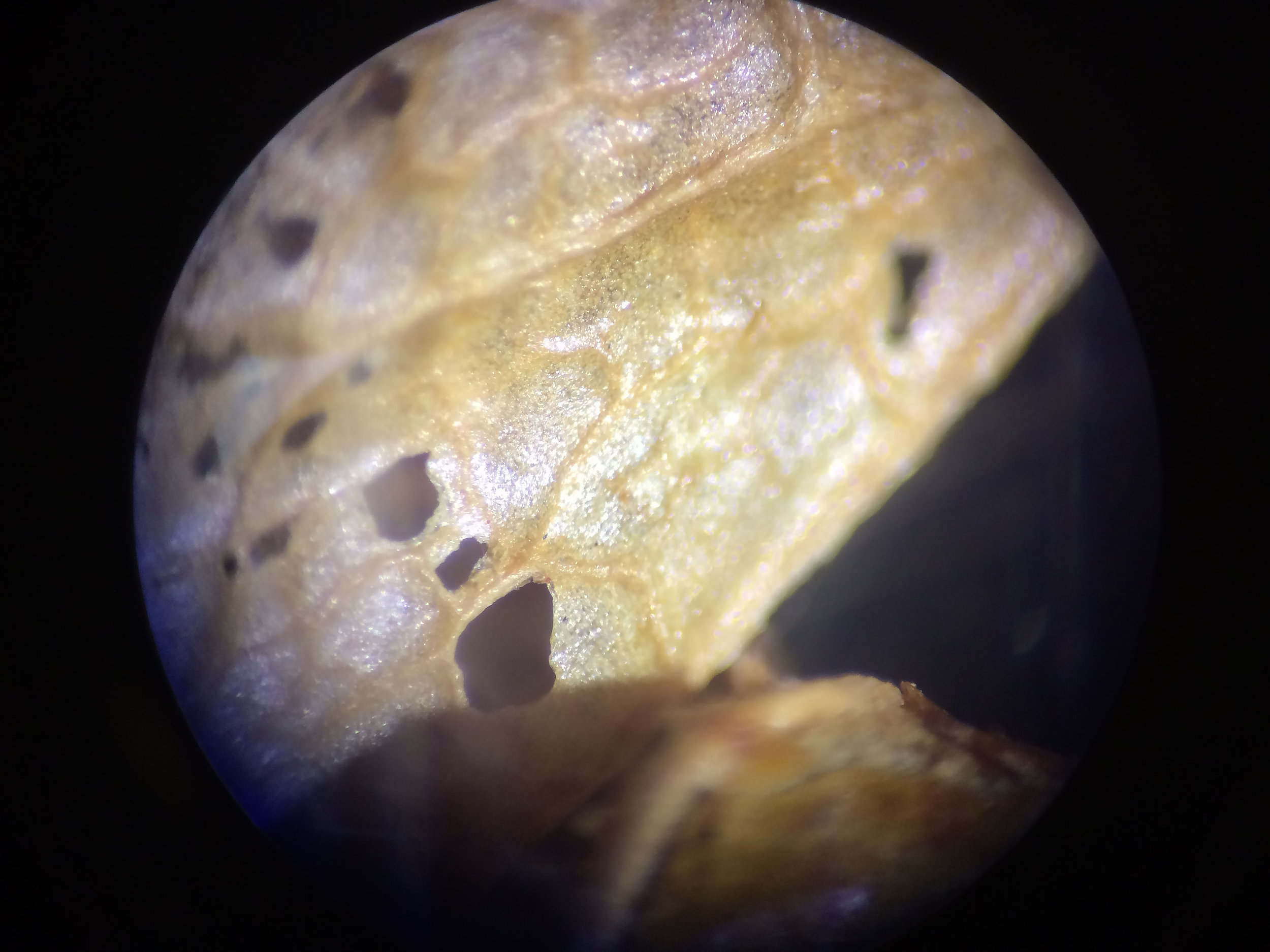

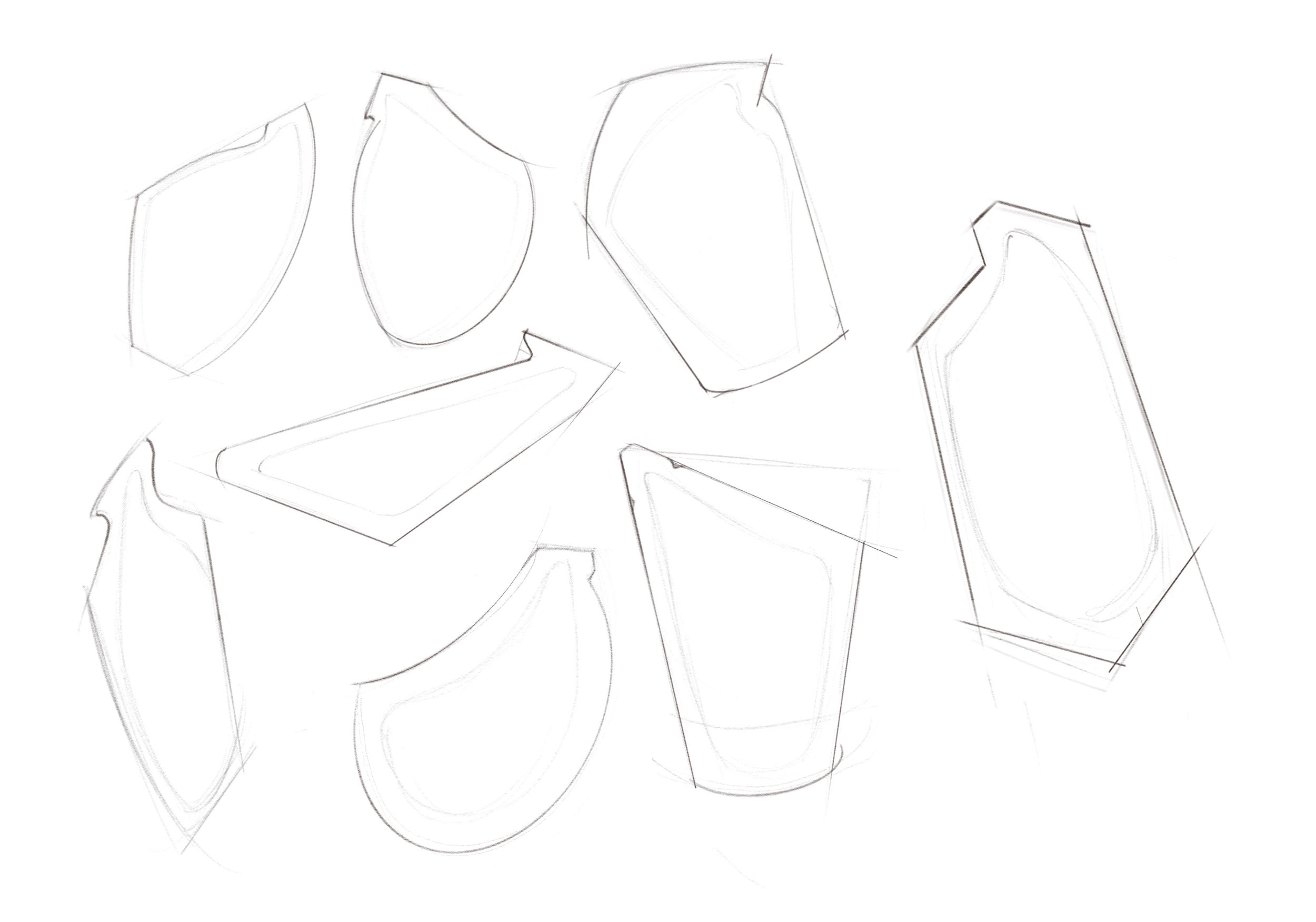

Through extensive research and experimentation, I ultimately produced a high-quality bioplastic that is both flexible and translucent, and can cure over the course of a few hours. Looking to nature for inspiration, I captured images of the material under a powerful Electron Scanning Microscope (ESM), and derived a pattern to laser-etch onto the surface of the same material. The ESM images also became inspiration for the final form of the “Gone” packet itself.

While the material I created is entirely biodegradable, it still has a considerable ecological footprint in the beginning of its life. The diverse ingredients necessary for my recipe are grown and manufactured all over the world, so it takes large amounts of energy to even get them in the same room.